Overcoming the “Coffee Ring Effect”

Polymeric additives enable homogeneous drying of dispersed particles

Have you ever spilled your cup of coffee? You may have noticed how the coffee dries into an intriguing stain with a bright center and a dark ring encircling it.

This “coffee ring” forms because the liquid evaporates faster at the edges, inducing a flow from the droplet interior towards the outside. Suspended solid coffee particles thus accumulate at the drop edge, causing the characteristic ring pattern.

Inks and any other liquid containing solid materials behave like coffee – particles accumulate around the edges upon drying. The resulting uneven particle distribution presents a major challenge in ink-jet printed electronic devices, as it can lead to failure and a loss of performance.

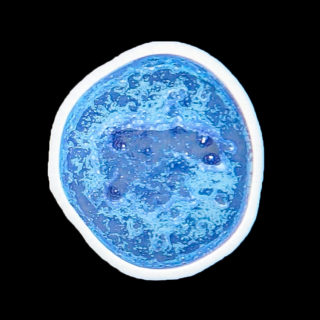

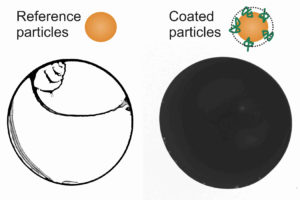

In Nature Communications, a team of researchers from the Department of Chemical and Biological Engineering at Friedrich-Alexander-Universität Erlangen-Nürnberg and the University of Edinburgh present a simple, yet versatile strategy to overcome the omnipresent coffee ring effect and achieve homogeneous drying patterns of particle dispersions. The trick the researchers apply is to modify dispersed particles with polymeric additives. This induces additional steric repulsion, which prevents particle accumulation at the droplet edge and promotes adsorption to the droplet surface, resulting in a homogeneous particle film upon drying.

Click to see the video animated by Institute of Particle Technology / FAU

Importantly, the presented method is independent of particle shape and is applicable to a variety of commercial pigment particles and different dispersion media. The simplicity and versatility of the method paves the way towards reliable coatings and ink-jet printed electronic devices in a wide range of advanced technologies.

The full article can be found on “Nature Communications”.

We are very proud that our MAP chair Nicolas Vogel led the team and several MAP lecturers, alumni and students contributed to the project.